July 18, 2023

July 18, 2023

A moist room, also known as a curing room or curing chamber, is essential for concrete testing because it provides optimal conditions for the curing process of concrete specimens. Curing refers to the process of maintaining favorable moisture and temperature conditions to promote the hydration and strength development of concrete.

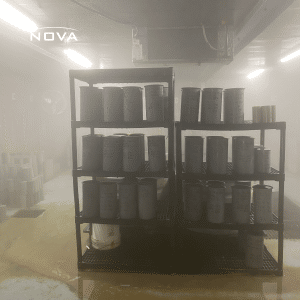

We’ve captured a behind the scenes snapshot of NOVA’s moist room located in Kennesaw, GA. Moist rooms look like a sauna or a room full of fog. Moist rooms require 95% humidity and 23 degrees C for hydration of the concrete, hence the foggy or misty look. Concrete cylinders are stored in the moist room for 7 days, 28 days, or more before being tested for compressive strength.

A moist room allows for temperature regulation, ensuring that the concrete specimens are cured within the desired temperature range. Also, in a moist room, the curing environment is controlled and uniform for all concrete specimens. This consistency in curing conditions ensures that all specimens undergo the same hydration process, allowing for accurate and reliable testing results. It helps eliminate variables that may arise from external factors, such as temperature fluctuations or exposure to drying conditions. The primary purpose of concrete testing is to assess the strength, durability, and other mechanical properties of the material. Proper curing in a moist room allows for the development of representative and reliable test results.

In summary, a moist room is of utmost importance for concrete testing as it creates an optimal environment for concrete curing. By controlling moisture, temperature, and providing uniform conditions, it promotes proper hydration, minimizes moisture loss, and enhances the accuracy and reliability of concrete testing results.

Photo credit: Stacy Hewitt, Marketing Coordinator, Kennesaw, GA Office